Innovative Production Technologies for large Component Assembly

Problem

Low quantities and long product life cycles result in labour-intensive assembly work. Among other things, this leads to the relocation of production to low-wage countries. In order to maintain the competitiveness of Germany as a high-wage location, there is a need for reconfigurable, automated production facilities for large component assembly.

Benefits of the solution

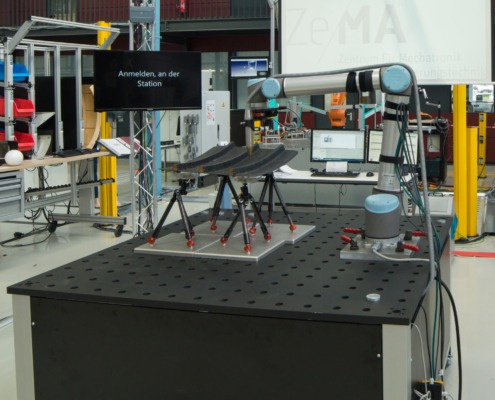

By the use of innovative production technologies, the assembly of large components becomes fast and flexible. A uniform control concept ensures resistance to errors through automatic quality inspection.

Used technologies

Adaptive and energy-efficient grippers based on shape memory alloys are used. Also, virtual planning of the real assembly processes by a Digital Twin as well as assistance systems for employee support and innovative control concepts for the fast integration of new components are used. Non-destructive inspection procedures for automatic quality control and documentation complete the overall package.

Fields of application

These technologies are used in the assembly of large components, e.g. in aircraft construction or wind power plants. A transfer to areas with similar challenges is possible.